3M Thin Bonding Tape

SECON is a 3M™ Select Converter

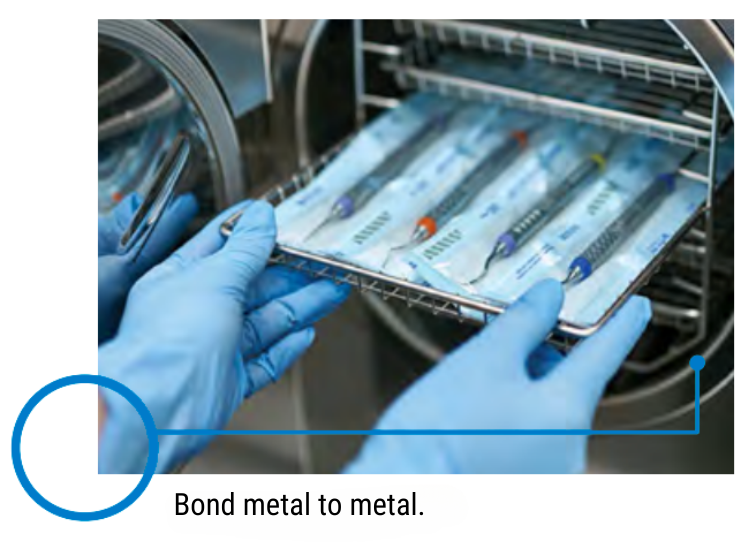

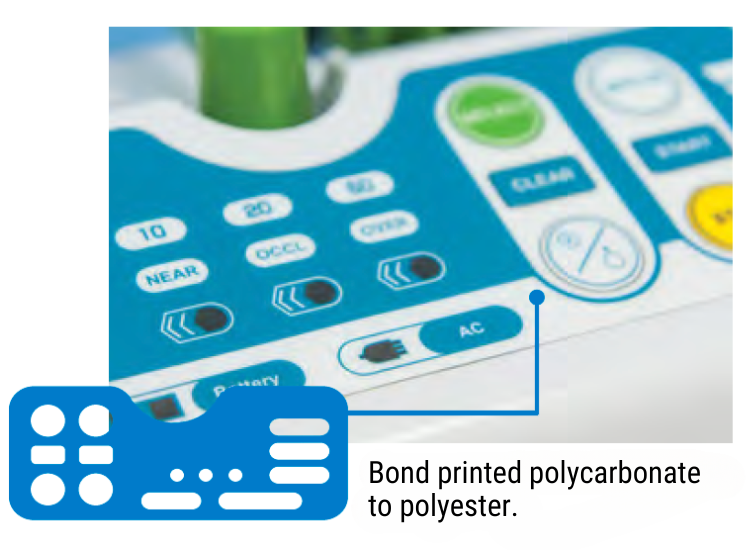

3M™ Thin Bonding Tapes provide a sleek, streamlined bonding solution, replacing bulky fasteners with a nearly invisible, industrial-strength bond. These tapes allow for precise customization to exact shapes needed in your final design, enhancing production flexibility by keeping the liner intact until application. From delicate electronics to heavy-duty machinery, 3M™ Thin Bonding Tapes provide exceptional shear strength, conformability, and high initial adhesion, supporting a wide range of applications.

In Stock

Rolls

Sheets

Slit to Width

Custom Parts

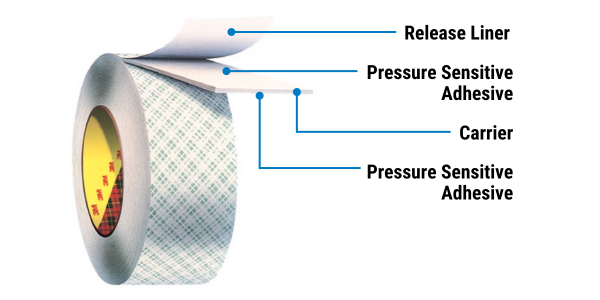

Double Coated Tapes

Double-coated tapes, also known as supported tapes, feature a carrier that holds or “carries” the adhesive, separating two adhesive layers. Depending on the application, carriers can be made from materials like paper, plastic film, tissue, or foam. A carrier allows for different adhesives on each side, suitable for bonding dissimilar materials that require different bonding properties.

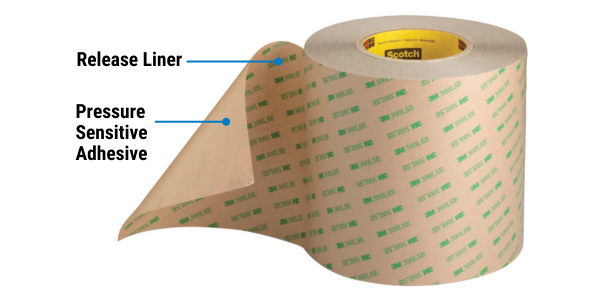

Adhesive Transfer Tapes

Adhesive Transfer Tape (ATT), or unsupported tape, features a thin adhesive layer with a liner for easy handling. Like most double-sided tapes, ATT is applied, then the liner is peeled off to apply the second substrate. Lacking a carrier, ATT consists of only one adhesive, but is not limited by a carrier’s temperature resistance, and is highly conformable to irregular surfaces.

3M Go-To Adhesives

From climate-controlled offices to harsh outdoor conditions, you need versatile, high-performance adhesives. 3M’s go-to adhesives bond everything from metals and glass to powder-coats and composites, offering durable, thin bonding solutions for any challenge.

From climate-controlled offices to harsh outdoor conditions, you need versatile, high-performance adhesives. 3M’s go-to adhesives bond everything from metals and glass to powder-coats and composites, offering durable, thin bonding solutions for any challenge.

100MP

Built for extremes. Indoor and out.

Designed for the toughest and most critical applications, 3M™ 100MP High Performance Acrylic Adhesive provides reliable performance not only at high temperatures (500°F/260°C), but also in extremely cold and variable temperatures.

- Up to 500°F (260°C) short-term heat resistance and outstanding solvent resistance

- Higher peel strength than most other acrylic formulations

- Exceptional shear strength even at elevated temperatures

200MP

Best for bonding metals and high surface energy substrates.

Tapes engineered with 3M™ Acrylic Adhesive 200MP adhere to a broad range of common substrates like metals and high surface energy plastics. With exceptional shear strength, anti-lifting power, and resistance to solvents and heat, it’s clear why leading designers choose 200MP.

- Up to 400°F (204°C) short-term heat resistance and excellent solvent resistance

- Outstanding adhesion to metal and high surface energy plastics

- Excellent shear strength to resist slippage and edge lifting

- Short-term repositionability for placement accuracy

300MP+

High performance for the world’s toughest environments.

Attach. Seal. Reduce noise. Expand your materials—and your design possibilities. Double-sided tapes made with 3M™ Acrylic Adhesive 300MP+ bond hard-to-bond textures and a wide range of other materials, even under UV exposure, humidity and more. It’s tough out there. Make sure your design lasts.

- Up to 250°F (121°C) short-term heat resistance and excellent initial adhesion

- Designed to bond most plastics, foams, fabrics, and substrates with rough or textured surfaces

- Excellent adhesion to foam, fabric, wood, carpet, particle board, fiberglass, vinyl and more

300LSE

Tapes for Hard-to-Bond Surfaces.

Tapes engineered with 3M™ High-Strength Acrylic Adhesive 300LSE have superpowers. They stick to hard-to-bond surfaces, such as various plastics (low surface energy substrates). They provide a strong hold and reliable performance—giving you more freedom to imagine. To design. To build.

- Up to 300°F (149°C) short-term heat resistance

- Excellent adhesion to low surface energy plastics, powder coated paints and lightly oiled metals

- Good chemical and humidity resistance

Your Trusted 3M Partner

At SECON, we specialize in converting 3M™ tapes into precise, customized parts tailored to your specific needs. Take advantage of our “3M Select Converter” status to benefit from lower costs, quick turnaround, and expert guidance. Contact us now.

At SECON, we specialize in converting 3M™ tapes into precise, customized parts tailored to your specific needs. Take advantage of our “3M Select Converter” status to benefit from lower costs, quick turnaround, and expert guidance. Contact us now.